Follow along as we help create coronavirus PPE for our local community to help those on the front lines. We have a form if you’d like to help donate to the cause or need PPE yourself!

Read MoreFrom my experience 3D printing, there are many times when you 3D print a part but it requires some extra work to clean it up afterwards. You can refine your machine and tweak settings to get it to print perfectly, but I’ve found it more efficient to make sure a model(s) 3D prints properly and then find new techniques to save time and thus money. So when I heard from a friend that you could use a lighter to clean up the stringing on my 3D printed parts, a lightbulb went off in my head - let’s try that this weekend! So here we are…

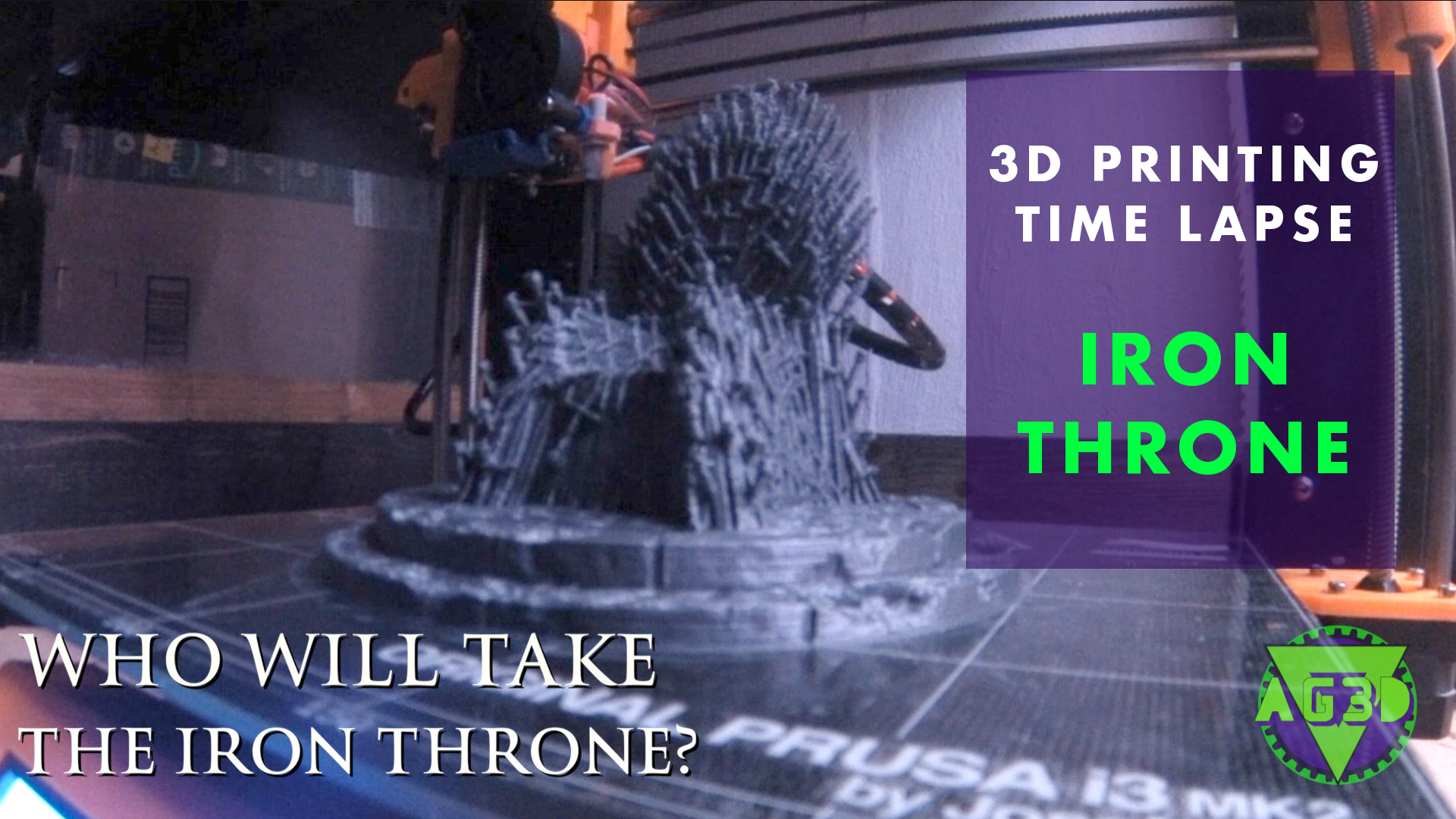

Read MoreThis model was 3D printed on the Prusa i3 MK2 with a metallic colored PLA from Amazon. The nozzle used was 0.6mm, and the layer height was 0.3mm which reduced our print time to just under 9 hours.

Read MoreWe just got our latest addition to our 3D Printer Fleet - the Creality CR-10 S5! This is the most MASSIVE 3D printer I have ever used, never mind assembled. I set up the camera to show the process of putting this giant 3D printer together and getting filament to extrude from the nozzle! Big first steps.

Read MoreHere's an interesting time-lapse mistake I caught on camera that actually shows anyone new to 3D printing what it looks like. Even the failure shows you how 3D printing works layer by layer. We were trying to 3D print all of the blades for the GoT Jon Snow Sword at once - clearly, not ready for that just yet.

Read More