THE PROJECT & GOALS:

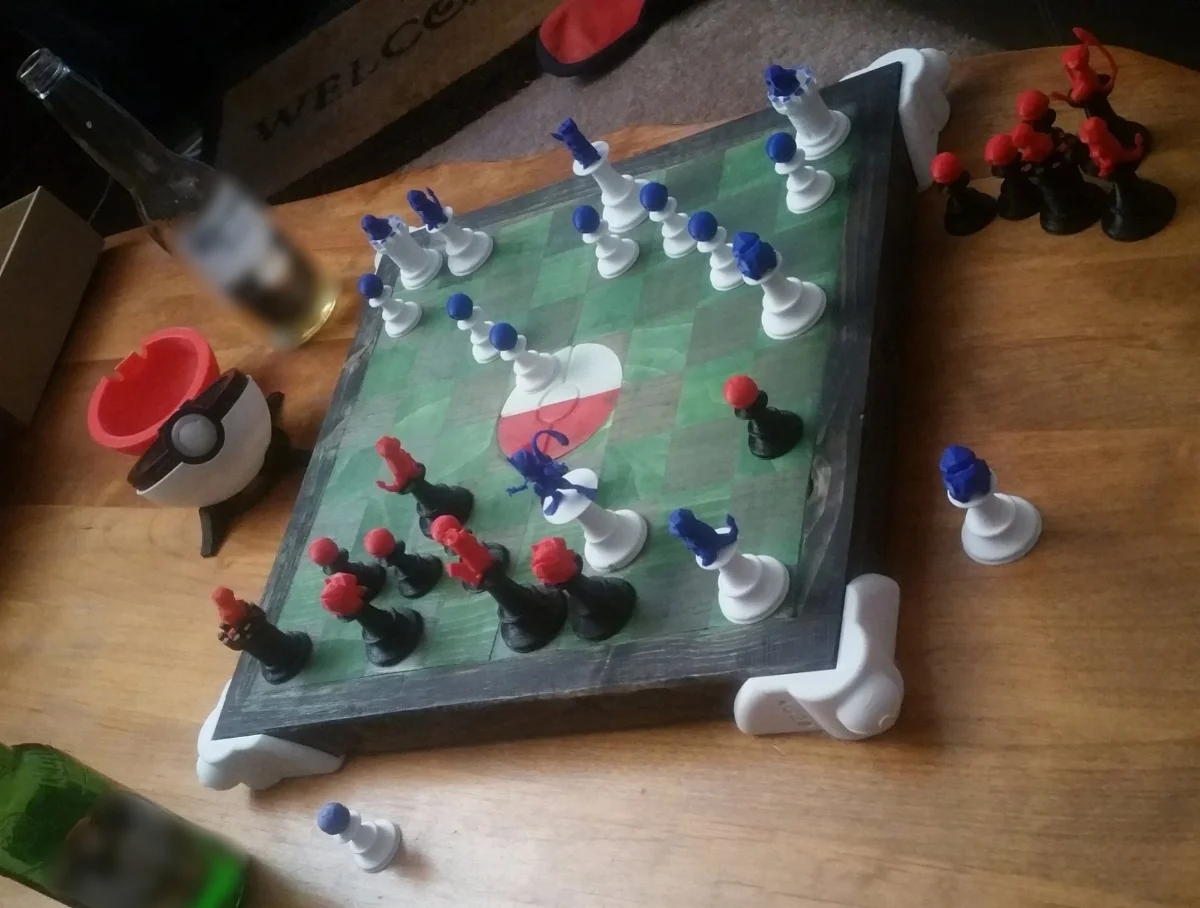

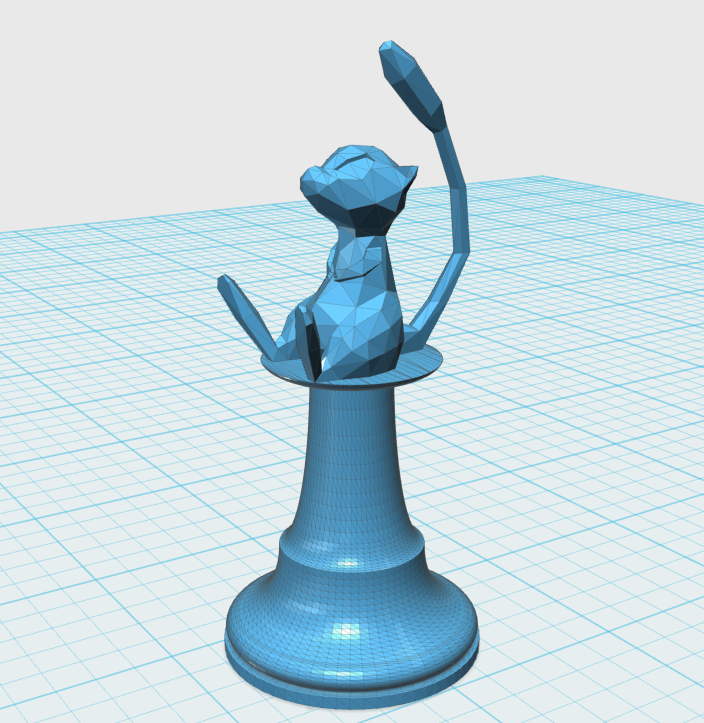

Custom Chess Set have become a great project for me lately. It started when I created my first Pokemon Chess set that I made as a Christmas present for my cousins, After the first chess set, I learned the basics of building a chess board and the 3D printing aspect of 3D printing multiple of the same objects at once. For the next Custom Chess Set project, I wanted to challenge myself and go further both in my woodworking and 3D printing skill sets.

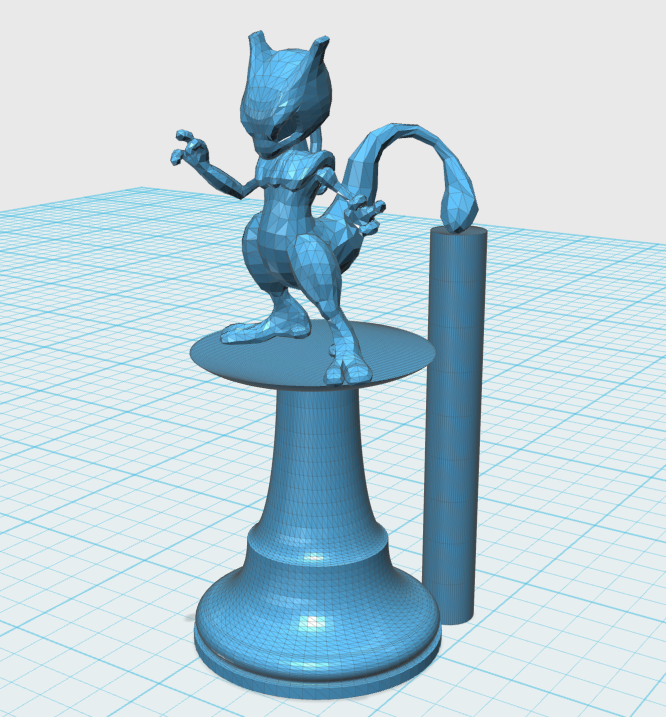

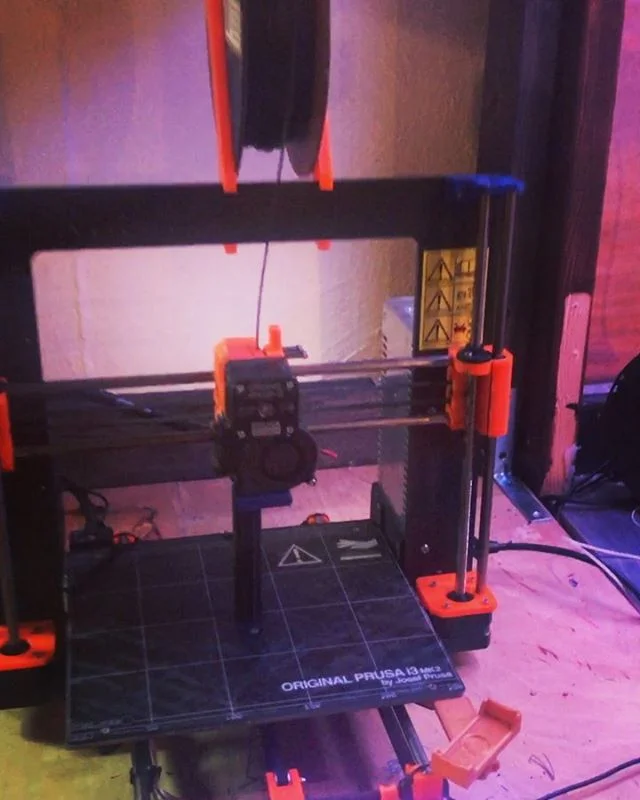

The initial idea was to create a Pokemon-Stadium-from-Super-Smash-Brothers themed Chess set. I had just received my newest 3D Printer, the Prusa i3 MK2 and with it came lots of upgrades and abilities. One of which, was the ability to print parts in multi-color.

MULTI-COLOR 3D PRINTING:

For desktop 3D printers, it’s possible to print more than one color or material in the same print. Essentially, a piece of G-Code is added to specify which layer(s) of the part you will change color or material. (G-Code, for those who are unaware is the language of the 3D Printer that contains instructions to make all the moves, temperatures changes, and extrusion of material needed to make the part).

For multi-color 3D Printing, the printer needs to stop printing and move the hot extruder away from the part, so you can change the material. In this case, I just needed to change colors. But you could also print other materials, even a water-soluble support material that would make support removal effortless.

Prusa Research makes the whole process of changing 3D printer language easy because errors in your g-code could be disastrous for your print if you don’t do it right. Simply add the g-code you want, and select the height where the printer needs to change material. The hardest part is finding the right layer height to choose. I found a nice simple way to figure it out.

First, take your layer height (.2 mm in this case) and then multiply it by the layer number (easily found in Simplify3D during print preview. Simply slide the END bar to the layer you want to change). That will be the number you need to set the G-Code to. It will also be your first change of color, so make sure it’s where you want it.

For me I wanted each Pokemon to be a separate color from the chess piece body. So I set the color change layer to the first layer of the Pokemon’s body. The cool thing was this meant I could use the same G-code for both color pieces. All I needed to do was start with white/black, and then change to Blue/Red when prompted. A nice buzz goes off when I need to change the filament. Easy.

3D PRINTING IN BATCH:

3D printing in batch is what I call 3D printing multiples of the same objects at the same time. For example, with the chess set all I had to do was create one multi-color g-code file for both the Red/Black and Blue/White pieces. All I needed to do was start with black and change to red, or start with white and change to blue. This made the whole process a lot easier, and saved me ALOT of time compared to changing colors for each of the two sets of 16 pieces of the chess set. I only had to change colors x12 times for the whole set to be created (as opposed to the REALLY inefficient way of changing for each piece, which would be 32 times. Not ideal).

3D PRINTING PARAMETERS:

The parameters stayed the same from the first Pokemon Chess Set, and are based on the original setting laid out by the creator of the chess set on Thingiverse.com (roshandp1)

INFILL %: 10 (RECTALINEAR)

LAYER HEIGHT: 0.200 mm (Normal)

SUPPORTS USED: YES

But I did not require rafts to print these, and the bottoms came out nice and smooth. Glue stick and a 60*C bed temperature was used to ensure the PLA would remain secure during printing.

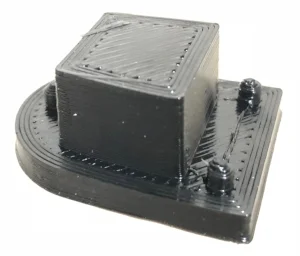

3D PRINTED INSERT:

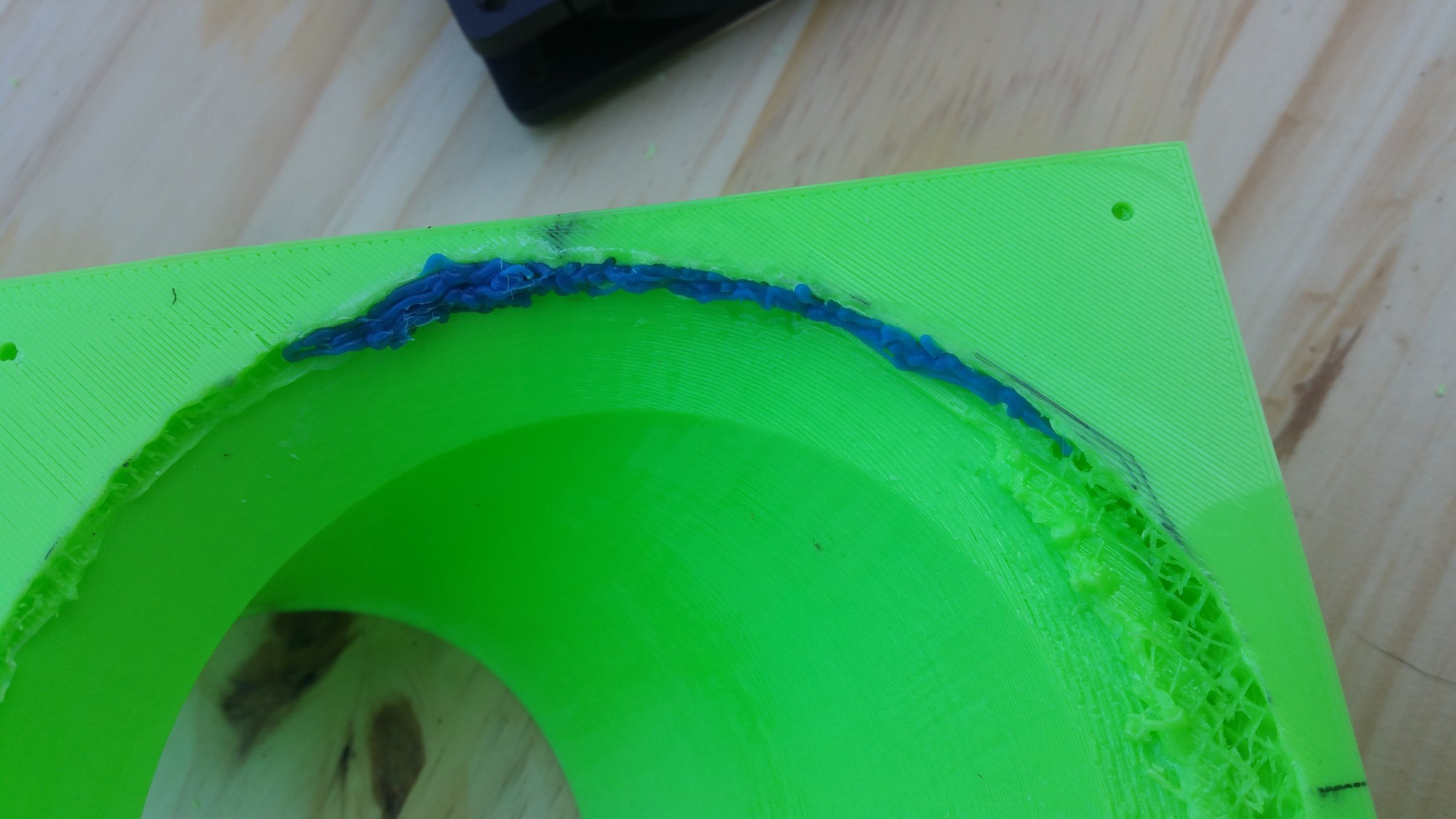

In order to create the Pokemon Stadium look, there needed to be a Pokeball in the center of the board. I used a 3" hole bit for my drill and created the hole in the center of the board, after it had been bonded together. I then designed and printed two different, almost symmetric pieces that I bonded together and pressed into the center of the board.

Next time, I will make the 3D printed piece slightly smaller than the hole, and not exactly 3". I assumed the plastic shrinkage would give me enough room, but the insert was very tight and required more work than was necessary. All in all, I was very happy with the final look of it and am excited to try out more 3D printed inserts in wood soon.

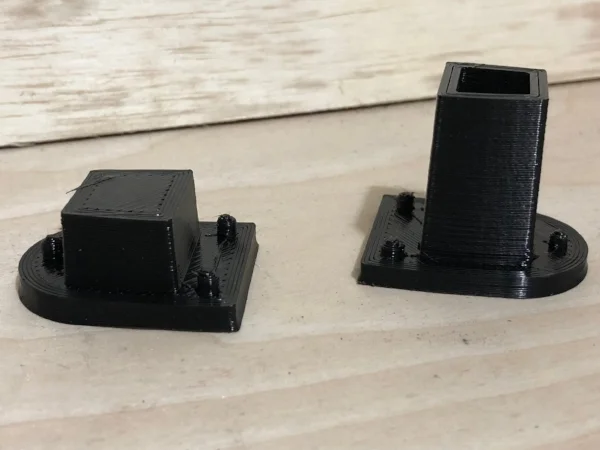

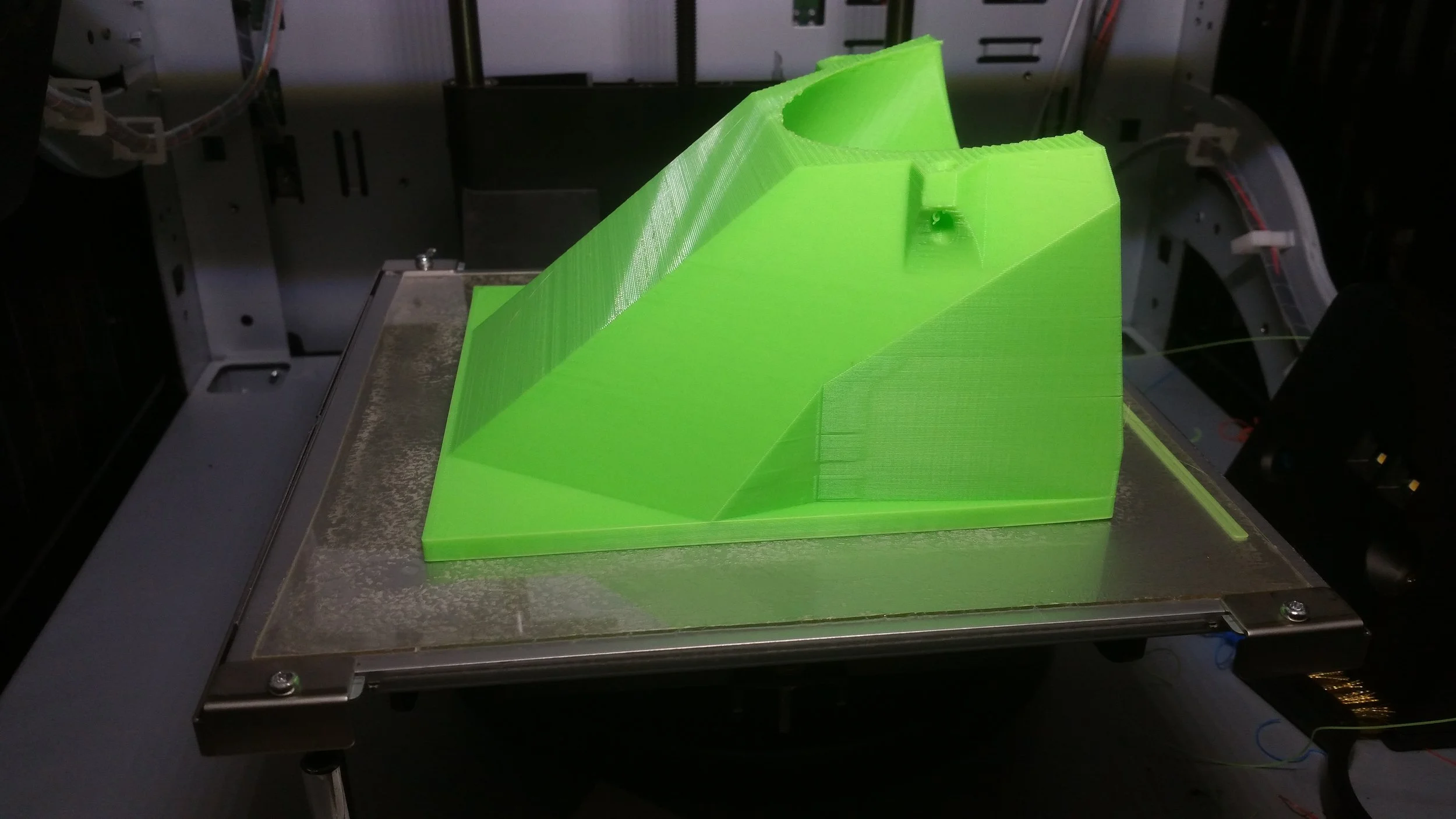

3D PRINTED STADIUM RISERS:

Until my carpentry skills get a little better (and I have more available tools) making something completely flat is difficult when you only have a belt sander. An easier and better looking plan was to create the stadium risers on each corner of the board. I incorporated a Pokeball and my logo in each riser. After some testing, and a little glue and felt, the risers were complete. I realized after that the my logo was visible from every view of the board, which was pretty cool to notice when it was done.